MIXING TECHNOLOGY

Mixing and blending of bulk solids is an important processing step in many industries. When processing dry bulk materials, the mixing equipment selected is crucial to ensure good homogenization of material particles, fast mixing cycle and high dispersant of additive.

AYS Engineering with our technology partners have the right mixer solution customized for process applications for wide range of industries that include:

Cement, Dry Mortar, Ceramics, Glass, Carbon paste, Battery paste, Friction linings, Foundries, Metallurgy

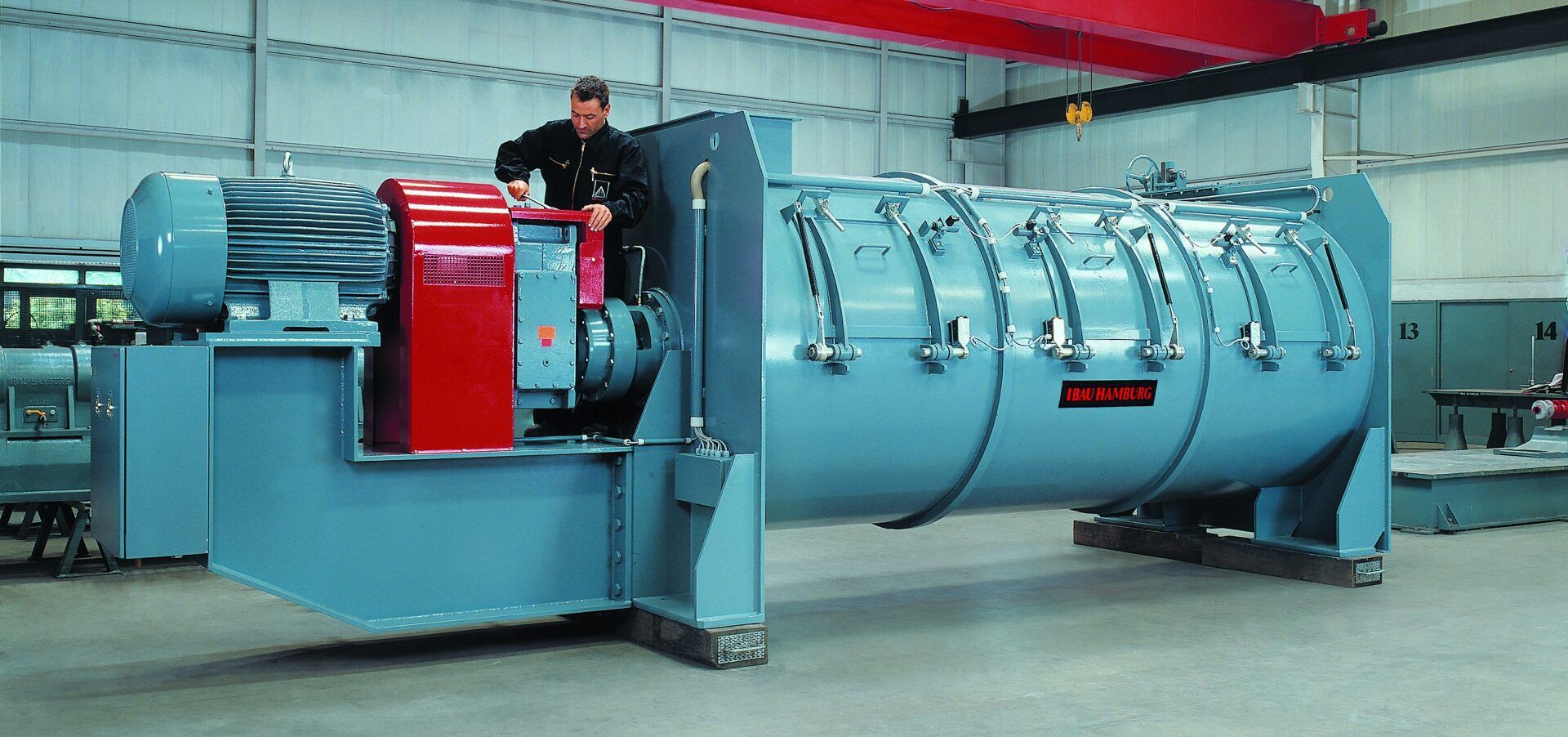

IBAU HORIZONTAL MIXER

Continuous mixing system with IBAU Flow-through mixers

For the mass cement production with 2-3 main components and with different degrees of grindability, it is advisable to perform a separate grinding of the components with the subsequent mixing in flow-through mixers. The grain size distribution of the individual components can be influenced separately.

Often the primary materials such as fly ash are already available in the required fineness, and joint grinding with clinker only consumes unnecessary energy. The use of flow-through mixers provides for a swift homogenization, additionally allowing an increase of the grinding output of the cement mills.

Discontinuous mixing systems, as the IBAU Batch-type mixer, are used for the production of special types of cement with a large number of main and secondary components and/or frequent product changes.

| IB-DM 2500 | IB-DM 3000 | IB-DM 4500 | IB-DM 6000 | IB-DM 8000 | IB-DM 10000 | IB-DM 12500 | IB-DM 15000 | |

|---|---|---|---|---|---|---|---|---|

| Throughput m3/h at 1 min. dwell time | 75 | 90 | 135 | 180 | 240 | 300 | 375 | 450 |

| Gross volume m3 | 2,5 | 3,0 | 4,5 | 6,0 | 8,0 | 10,0 | 12,5 | 15,0 |

| Net volume m3 | 1,25 | 1,5 | 2,25 | 3,0 | 4,0 | 5,0 | 6,25 | 7,5 |

| Required power kW | 45 | 55 | 75 | 90 | 110 | 132 | 132 | 160 |