AUMUND: PREMAS 4.0 Predictive Maintenance Solution

Predictive Maintenance Solution for Conveying Technology

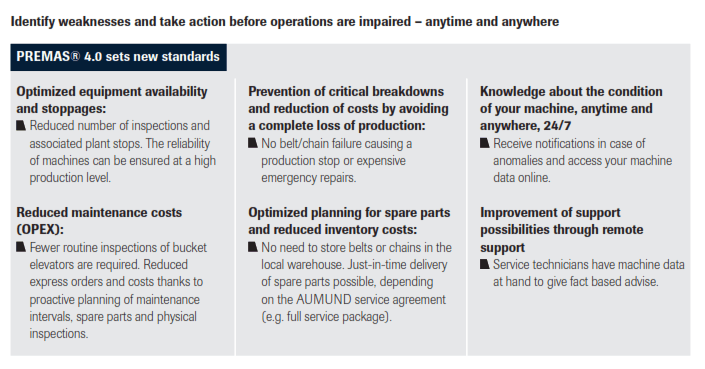

AUMUND introduces the Predictive Maintenance Solution, PREMAS® 4.0 to further enhance its service support to customers. Reactive or insufficient maintenance often leads to unplanned stops, high maintenance costs and huge losses due to production halts. This can be avoided by having a predictive maintenance system in which, the system could predict potential failures that the plant users can rely on for uninterrupted operation and maximum production. AUMUND now would be able to extend the proven physical inspections by introducing the all-new online monitoring system named PREMAS® 4.0 Predictive Maintenance Solution.

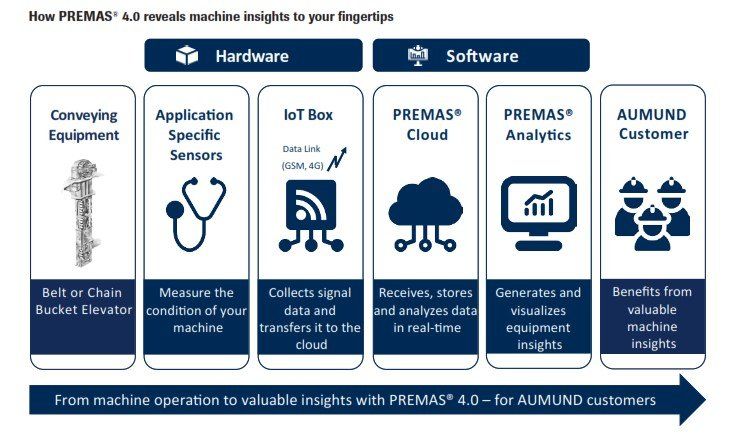

PREMAS® 4.0 could provide early detection of wear and aging of important machine components to the plant operators. The latest sensor technologies are combined with real-time data acquisition and analysis to enable permanent online condition monitoring of the machine on any mobile device. In addition to the condition of the machine, PREMAS® 4.0 also provides an estimation of the remaining service life of critical machine components.

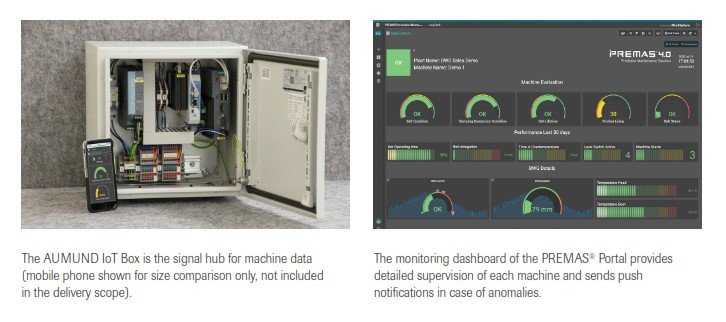

The Predictive Maintenance Solution is specially made for conveying equipment in the heavy industry. Every machine receives a hardware package. Provided field sensors as well as some existing signals from the plant control system (motor current, level switch, speed switch, drift warning) will be connected to the IoT Box, which sends the collected data through mobile connectivity to the PREMAS® Cloud. There, the data will be analyzed based on the latest technologies for predictive analytics (e.g. algorithms, machine learning …). The PREMAS® Portal visualizes and provides all relevant data for a complete online condition monitoring, securely online accessible to authorized users 24/7 through any mobile or desktop device.